We can provide more personalized favor and size.

-

Jan 23. 2026

What Culinary and Food Processing Scenarios Are Ideal for Sachet Tomato Paste?Sachet Tomato Paste is a versatile ingredient found in kitchens and food processing plants around the world. Whether you're a professional chef, a home cook, or involved in large-scale food production, sachet tomato past...

Read More -

Jan 16. 2026

What are the advantages of sachet packaging in preserving tomato sauce?In the food industry, packaging plays a crucial role not only in protecting products but also in enhancing consumer convenience and prolonging shelf life. Among various packaging formats, Sachet Tomato Paste has emerged ...

Read More -

Jan 09. 2026

How does the origin of the tomatoes affect the quality of Sachet Tomato Paste?Sachet Tomato Paste has become a staple in kitchens around the world, valued for its convenience, concentrated flavor, and versatility. However, the quality of this product is deeply influenced by the origin of the tomat...

Read More

Tomatoes are an indispensable core raw material for Canned Tomato Sauce. The planting process is not only related to the yield, but also directly determines the final quality and taste of the ketchup. Starting from seed selection, it is necessary to carefully select tomato varieties that are highly adaptable, disease-resistant, plump and rich in natural flavor. This is the first step in laying the foundation for high-quality ketchup. Next, land preparation is equally critical, including deep plowing, reasonable crop rotation and application of organic fertilizers to provide a fertile and healthy soil environment for tomato growth.

Irrigation and fertilization are important links in daily management and need to be scientifically arranged according to the needs of the tomato growth cycle. Timely and appropriate irrigation can not only ensure that the plants are well hydrated, but also promote fruit development; while precise fertilization can balance soil nutrients and enhance the nutritional value and flavor of tomatoes. In terms of pest and disease control, a comprehensive prevention and control strategy should be adopted, such as a combination of biological control, physical isolation and chemical control, to minimize the use of chemical pesticides to protect the environment and consumer health.

The picking process is equally important. It should be done when the tomatoes are fully ripe and bright in color to avoid picking too early or too late to affect the quality of tomatoes. Picked tomatoes should be pre-cooled immediately to maintain their freshness and extend their shelf life. When producing Canned Tomato Sauce, in addition to fresh tomatoes, natural condiments such as sugar, salt, vinegar, and spices may be added to adjust the sweetness, acidity, and flavor of the ketchup to meet the taste preferences of different consumers. The amount of these additives used must be strictly controlled to ensure compliance with national food safety standards while maintaining the natural purity of the ketchup.

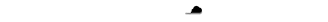

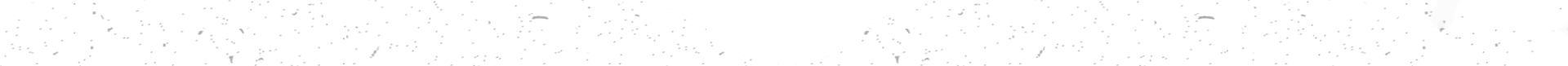

In terms of packaging, ketchup cans are made of special metal materials, such as tinplate or aluminum alloy. These materials not only have good sealing properties and can effectively prevent air and microbial intrusion, but can also withstand a certain amount of pressure, making them convenient for long-distance transportation and long-term storage. The label and instructions on each can of ketchup play the role of information transmission, clearly marking the product name, ingredient list, production date, shelf life, consumption recommendations, and manufacturer information, so that consumers can eat with confidence.

During the processing, tomatoes need to go through a series of pre-treatment steps such as washing, peeling, seeding, and crushing to remove impurities and facilitate subsequent boiling. During boiling, the heat and time are precisely controlled, and pre-mixed seasonings are added to make the tomato sauce reach the ideal taste and color. Before filling, the tomato sauce must also undergo strict quality inspection, including sensory evaluation (such as color and taste), physical and chemical testing (such as pH value, sugar content, salt content) and microbiological testing to ensure that each batch of products meets the established quality standards.

For exclusive discounts and the latest offers, please enter your address and information below.

EN

EN  English

English Français

Français 中文简体

中文简体

No.1 Tongqianqiao Road, Dongpu Village, Simen Town, Yuyao, Zhejiang Province

No.1 Tongqianqiao Road, Dongpu Village, Simen Town, Yuyao, Zhejiang Province  nbms@nbtomato.com

nbms@nbtomato.com